Products Description

Brief Introduction

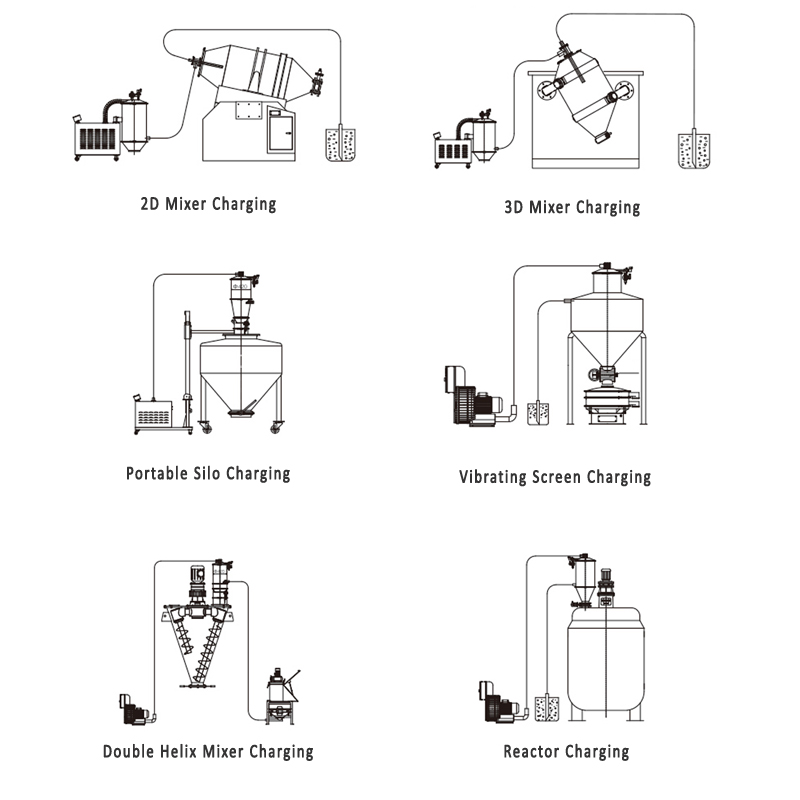

A vacuum feeder is a vacuum conveying device designed for powdery materials, granular materials, and mixed powdery-granular materials. It can automatically convey various materials into the hoppers of equipment such as silos, packaging machines, injection molding machines, and crushers. It can also directly convey mixed materials into mixers (e.g., V-type mixers, two-dimensional mixers, three-dimensional mixers, etc.). This equipment reduces workers' labor intensity and solves problems such as dust overflow during feeding. It is an essential device for pharmaceutical factories and food factories to obtain GMP certification, promote clean production, and achieve standardized workshop operations.

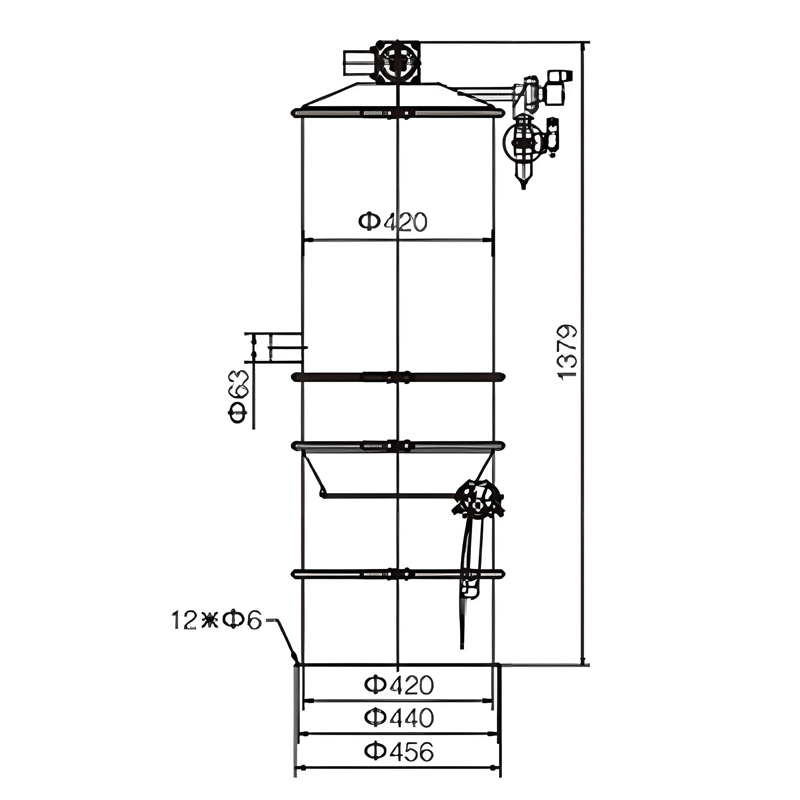

A vacuum feeder is composed of the following components: a vacuum pump (oil-free and water-free), a vacuum hopper, a filter (with multiple options including polyester film-coated filters, PE filters, 316L stainless steel filters, or titanium metal filters), a compressed air back-blowing device, a pneumatic discharge gate device, an automatic material level control device, a stainless steel suction nozzle, and a conveying hose. The entire system features rational design and exquisite manufacturing.

Features

1. The conveying pipelines can be flexibly configured, thereby optimizing the rationality of the factory's production process flow.

2. The conveying system is fully enclosed, minimizing dust emission and dispersion, which enables the achievement of good environmental hygiene.

3. There are few moving parts, making maintenance and upkeep convenient, and the system is easy to automate.

4. It features high efficiency in bulk material conveying, reducing packaging, loading/unloading, and transportation costs.

5. It can prevent the conveyed materials from being damped, contaminated, or mixed with other impurities, thus ensuring the quality of conveyance.

6. During the conveying process, multiple process operations can be realized simultaneously, such as mixing, crushing, classification, drying, cooling, dust removal, and other chemical reactions.

7. It allows for long-distance operations where materials concentrated at multiple points are conveyed to a single location, or materials from one location are distributed to multiple points.

8. The equipment has a simple structure, making manufacturing, processing, and installation relatively convenient; it also requires low control costs and has a short construction period.

9. It has high conveying efficiency, and the equipment does not require return transportation.

10. It is conducive to realizing bulk transportation, saving packaging materials and reducing transportation costs.

11. It provides good labor hygiene conditions.

12. During the conveying process, intermediate treatments such as sorting and drying can also be carried out independently.

13. It can convey materials in a heated state and play a cooling role during the conveying process.

Parameters

Model | Motor Power | Transport Capacity | Suction Port | Working Pressure | Gas Consumption | Size |

ZKS-1 | 1.5KW | 400kg/h | φ38mm | 0.4-0.6Mpa | 500NL/min | φ290*802mm |

ZKS-2 | 2.2KW | 600kg/h | φ39mm | 0.4-0.6Mpa | 500NL/min | φ290*802mm |

ZKS-3 | 3KW | 1200kg/h | φ51mm | 0.4-0.6Mpa | 500NL/min | φ290*952mm |

ZKS-4 | 5.5KW | 2500kg/h | φ51mm | 0.4-0.6Mpa | 500NL/min | φ420*1216mm |

ZKS-6 | 5.5KW | 3200kg/h | φ51mm | 0.4-0.6Mpa | 500NL/min | φ420*1216mm |

ZKS-7 | 7.5KW | 6000kg/h | φ63mm | 0.4-0.6Mpa | 500NL/min | φ420*1379mm |

ZKS-10-6 | 7.5KW | 6000kg/h | φ76mm | 0.4-0.6Mpa | 500NL/min | φ600*1907mm |

ZKS-20-5 | 11KW | 5000kg/h | φ102mm | 0.4-0.6Mpa | 500NL/min | φ800*2070mm |

Note: For detailed parameters, please contact us. Equipment selection can be made based on your requirements. | ||||||