Products Description

Brief Introduction

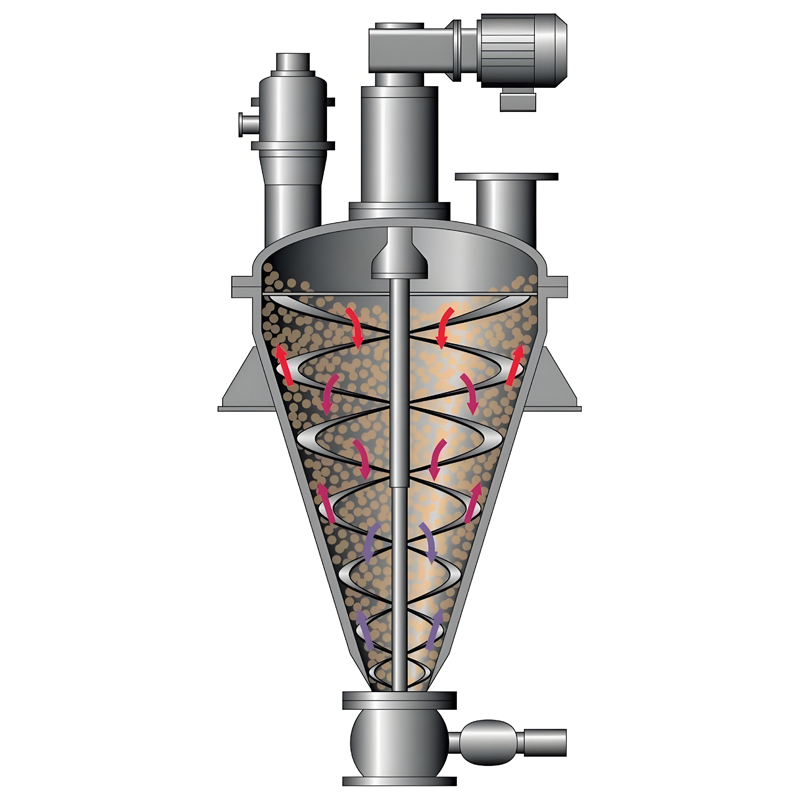

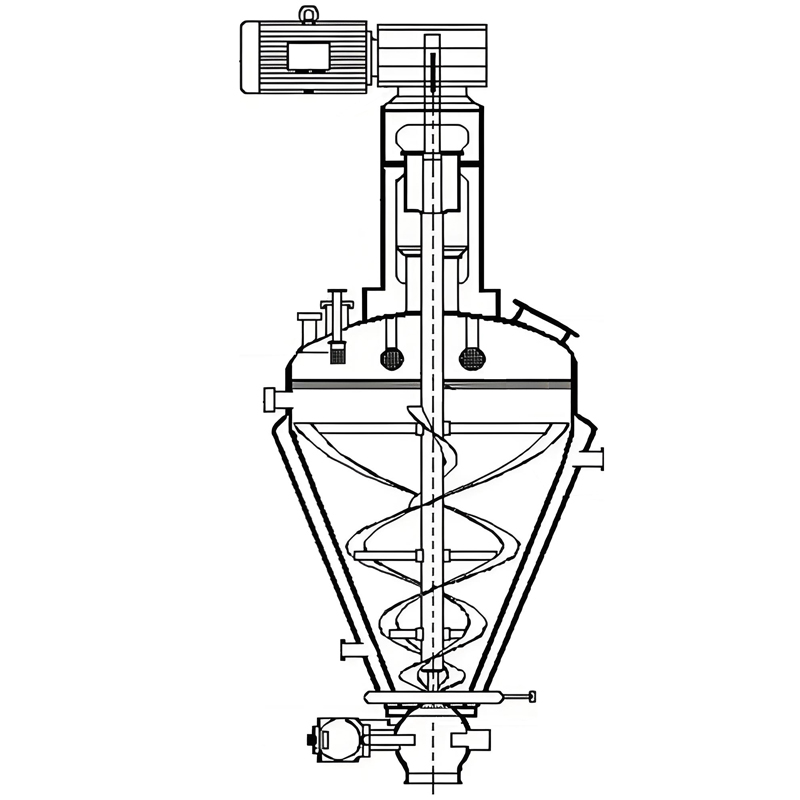

A Cone Mixer, also known as a Double Cone Blender, is a versatile industrial mixing machine characterized by its distinctive conical-shaped vessel. It is designed for the homogeneous dry blending of powders and granules. The mixer operates by rotating the conical vessel around a central horizontal axis, causing the materials to undergo a continuous tumbling and shearing motion. This gentle yet effective action ensures that particles are distributed evenly throughout the batch without the high shear or heat generation associated with other mixer types.

Its simple yet efficient design makes it a fundamental and widely used piece of equipment in industries where a uniform dry mix is critical.

Features

1. High Mixing Homogeneity and Gentle Action

Uniform Blending: The combination of tumbling and the splitting/folding action as the material moves through the cone geometry ensures a highly consistent and homogeneous mixture, even for formulations with minor components.

Gentle on Materials: The low-shear mixing process is ideal for fragile granules, preventing particle degradation, dusting, or altering the physical characteristics of the ingredients.

2. Efficient Discharge and Minimal Residuals

Complete Discharge: The conical shape guides all material towards the central discharge valve, ensuring virtually complete emptying. This minimizes batch-to-batch cross-contamination and material loss.

Easy to Clear: The smooth, uninterrupted internal surfaces allow for quick and thorough cleaning.

3. Robust, Hygienic Design and Easy Maintenance

High-Quality Construction: Typically manufactured from 304 or 316L stainless steel with polished internal surfaces, making it durable, corrosion-resistant, and suitable for sanitary applications.

Compliance with Standards: The design can be adapted to meet GMP (Good Manufacturing Practice) requirements for the pharmaceutical and food industries, including features like CIP (Clean-in-Place) systems.

Simple Mechanics: The straightforward mechanical design, often with a direct drive system, translates to high reliability and low maintenance requirements.

4. Process Versatility and Flexibility

Adaptable to Various Products: Well-suited for a wide range of bulk densities and particle sizes. It can also be adapted for performing light coating or agglomeration processes.

Customizable Options: Can be equipped with internal agitators (breaker bars) to prevent clumping, spray nozzles for liquid addition, jackets for heating/cooling, and vacuum or inert gas systems for processing sensitive materials.

5. Operational Safety and Cost-Effectiveness

Enclosed Operation: The sealed vessel contains dust, protecting the operator and the environment. Interlocked guards ensure safe operation during rotation.

Low Operating Costs: Due to its simple design, energy consumption is relatively low, and maintenance costs are minimized over the equipment's long service life.

Application Scenarios

The Cone Mixer is a staple in industries requiring gentle, yet thorough, dry blending:

Pharmaceutical Industry: Blending active pharmaceutical ingredients (APIs) with excipients for tablet and capsule formulations.

Food Industry: Mixing spices, dry soup mixes, beverage powders, and flour-based products.

Chemical Industry: Homogenizing pigments, dyes, fertilizers, and plastic compounds.

Cosmetics Industry: Blending powders for makeup and other cosmetic products.