Products Description

Brief Introduction

When compressed air is supplied to the vacuum generator, the vacuum generator creates negative pressure to form a vacuum airflow. Materials are sucked into the suction nozzle, forming a solid-gas flow, which then reaches the hopper of the feeder through the suction pipe. The filter completely separates the materials from the air; when the hopper is full of materials, the controller automatically cuts off the air supply, the vacuum generator stops working, and at the same time, the hopper door opens automatically, allowing the materials to fall into the hopper of the equipment. Meanwhile, compressed air automatically cleans the filter through the pulse backblow valve. When the set time is reached or the level sensor sends a feeding signal, the feeder is automatically started.

Features

It uses compressed air to generate high vacuum through a vacuum generator for material conveyance, eliminating the need for a mechanical vacuum pump. It boasts advantages such as a simple structure, compact size, maintenance-free operation, low noise, easy control, elimination of material static electricity, and compliance with GMP requirements.

The high vacuum produced by the vacuum generator prevents stratification of the conveyed materials, ensuring the uniformity of the mixed material components.

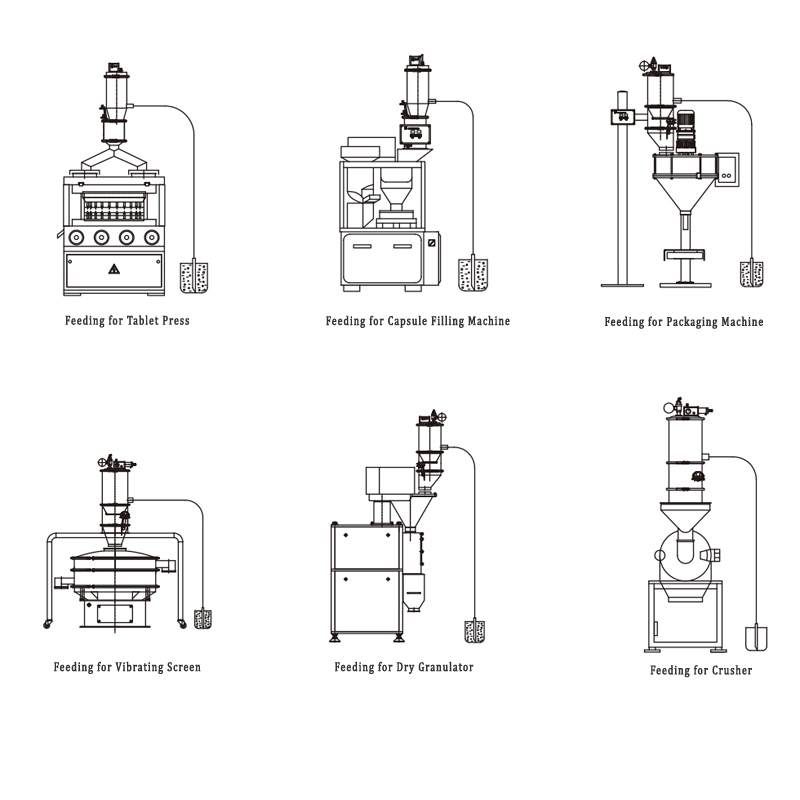

It is an automatic feeding equipment for machines including tablet presses, capsule filling machines, dry granulators, packaging machines, crushers, and vibrating screens.

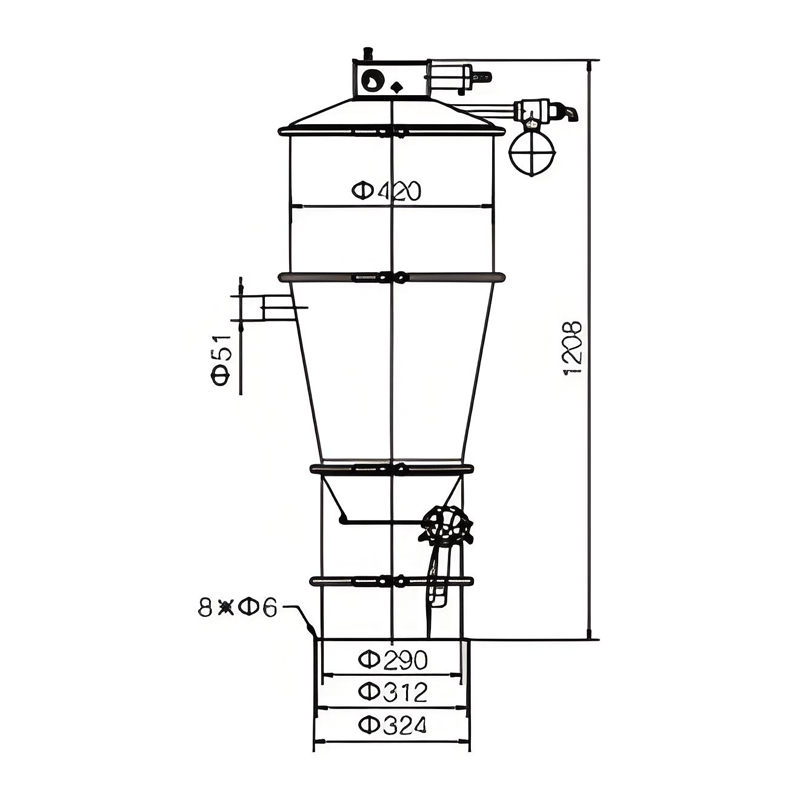

Parameters

| MODEL | Bin Volume | Transport | Working | Gas | Size |

| Capacity | Pressure | Consumption | |||

| QVC-1 | 1.1L | 50-300kg/h | 0.4-0.6Mpa | 180NL/min | φ140*491mm |

| QVC-2 | 6L | 100-700kg/h | 0.4-0.6Mpa | 360NL/min | φ213*628mm |

| QVC-3 | 12L | 300-1500kg/h | 0.4-0.6Mpa | 720NL/min | φ290*1047mm |

| QVC-4 | 42L | 600-3000kg/h | 0.4-0.6Mpa | 1440NL/min | φ420*1361mm |

| QVC-5 | 60L | 900-6000kg/h | 0.4-0.6Mpa | 2880NL/min | φ420*1413mm |

| Note: For detailed parameters, please contact us. Equipment selection can be made based on your requirements. | |||||