Products Description

Brief Introduction

An Industrial Dust Collector is a mechanical system designed to capture, filter, and separate airborne particulate matter—such as dust, smoke, and fumes—generated during industrial manufacturing processes. It is far more than a simple "vacuum cleaner"; it is a sophisticated Air Pollution Control System engineered to:

*Protect Operator Health: Prevent the inhalation of hazardous dust by personnel.

*Ensure Production Safety: Mitigate the risk of explosions caused by combustible dust.

*Enhance Product Quality: Prevent contaminants from settling on products, ensuring high quality.

*Comply with Environmental Regulations: Ensure exhaust emissions meet stringent environmental standards.

*Recover Valuable Materials: Capture and reclaim valuable particulate matter (e.g., precious metal powders, active pharmaceutical ingredients) for reuse.

The core working principle involves using a fan to create negative pressure, drawing dust-laden air into the unit. The air then passes through a filter medium (such as filter bags or cartridges) or is treated by other physical principles (like centrifugal force, electrostatic attraction, or water scrubbing) to separate the particles. The cleaned air is subsequently discharged back into the workspace or the atmosphere.

Features

Investing in a suitable industrial dust collector delivers significant, multi-faceted returns that go far beyond simply "cleaning the air."

1. Ensuring Occupational Health & Safety (People-Centric)

Prevents Occupational Diseases: Effectively captures hazardous particles such as silica dust, welding fumes, and heavy metal particulates, fundamentally preventing occupational illnesses like pneumoconiosis, metal fume fever, and asthma.

Creates a Comfortable Work Environment: Reduces airborne particulate matter, improves visibility, and minimizes odors, fostering a healthier and more comfortable environment for employees. This boosts morale and enhances productivity.

2. Enhancing Production Safety & Risk Reduction (Proactive Prevention)

Prevents Dust Explosions: Many industrial dusts (e.g., from grain, wood, metals, chemicals) are combustible. By continuously removing these dusts, collectors drastically reduce the risk of catastrophic workplace dust explosions.

Reduces Equipment Failure Rates: Dust can infiltrate precision machinery, electrical control systems, and moving parts, leading to wear, overheating, and failure. Dust collectors protect other production assets, extending their service life and minimizing downtime.

3. Ensuring Product Quality & Consistency (Lean Manufacturing)

Prevents Cross-Contamination: In industries like food processing, pharmaceuticals, electronics, and lithium battery manufacturing, even micron-level dust can lead to product contamination, performance issues, or entire batch rejection. Dust collectors are critical for maintaining cleanroom standards and product purity.

Reduces Surface Defects: In processes like painting, coating, and precision assembly, airborne dust is a primary cause of product surface imperfections. Dust collectors ensure the finish and quality of the final product.

4. Enabling Resource Recovery & Cost Savings (Economic Benefits)

Material Recovery: In many processes, the collected dust is itself a valuable raw material (e.g., precious metal catalysts, milk powder, APIs). Dust collectors can efficiently recover these materials, allowing them to be reintroduced directly into the production line, significantly reducing material loss costs.

Energy Efficiency & Cost Reduction: Clean equipment (e.g., HVAC systems, heat exchangers) operates more efficiently. Furthermore, modern dust collectors often feature intelligent control systems that automatically adjust fan power based on dust load, resulting in significant energy savings.

5. Meeting Regulatory Requirements & Social Responsibility (Compliance & Image)

Regulatory Compliance: Stringent occupational health and safety (e.g., OSHA) and environmental protection (e.g., EPA) regulations exist worldwide. Installing an effective dust collection system is essential for legal operation and avoiding substantial fines and litigation.

Enhances Corporate Image: A company that demonstrably prioritizes employee health and environmental protection earns greater trust from customers, partners, and the community, thereby enhancing its brand reputation and social responsibility profile.

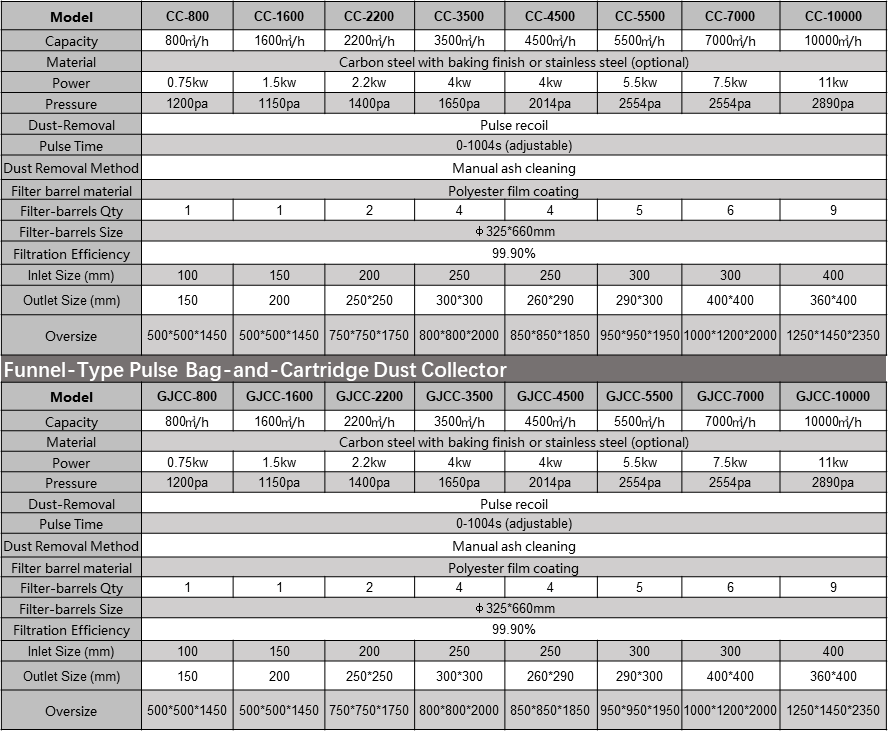

Parameters