Products Description

Brief Introduction

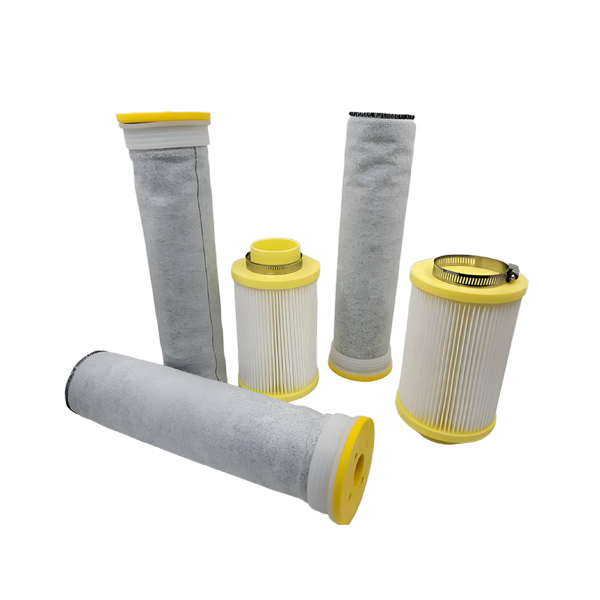

Cloth Bag Filter Element is a traditional yet highly efficient filtration solution widely used in industrial dust collection systems. These filter bags, typically made from woven or needle-felt fabric materials, function as the primary filtration medium in baghouse dust collectors. They operate on the principle of surface and depth filtration to capture dust particles from gas streams while allowing clean air to pass through.

The filter element is constructed from specialized filter fabrics such as polyester, polypropylene, Nomex, or P84, selected based on specific application requirements including temperature resistance, chemical compatibility, and filtration efficiency. Standard sizes range from 4 to 8 inches in diameter and 2 to 10 feet in length, with various mounting configurations available.

Features

1. High Filtration Efficiency

Captures fine particulate matter with efficiency exceeding 99.9%

Effective for particles ranging from sub-micron to larger sizes

Consistent performance across varying dust loads

2. Excellent Economic Value

Lower initial cost compared to many cartridge filters

Durable construction provides long service life

Cost-effective replacement and maintenance

3. Versatile Material Selection

Multiple fabric options available for different temperature ranges

Special coatings (PTFE, silicone) for enhanced performance

Material choices for corrosive and high-temperature applications

4. Easy Maintenance and Replacement

Simple installation and removal processes

Individual bag replacement without system shutdown

Visual inspection capability for condition monitoring

5. Adaptable to Various Applications

Suitable for diverse industries from woodworking to mineral processing

Handles various dust types including abrasive and sticky materials

Customizable sizes and specifications

Application Scenarios

Cement Industry: Kiln feed, clinker cooling, cement grinding

Metallurgical Industry: Blast furnace, smelting operations, metal processing

Chemical Industry: Powder processing, material conveying, production processes

Power Generation: Coal-fired boilers, biomass combustion, ash handling

Food Processing: Grain handling, powder ingredients, material transfer